Strecker Success Story Very high weld joint quality with

The challenge

To enable continuous operations, the end of one coil must be connected to the beginning of the next coil during production.

With larger wire diameters such as WR20, WR18 or WR16 mm reinforcing steel, it is very strenuous for operators to pull the wire ends to be welded out of the system far enough so that they can be joined in a horizontal line using a conventional welding machine.

After welding, the resulting wire loop must then be forced back into the system, and in the process the loop often becomes tangled and obstructs the pay off. Consequently, the company was looking for ways to optimize processes and at the same time wanted to relieve the operator of heavy physical labour.

The solution

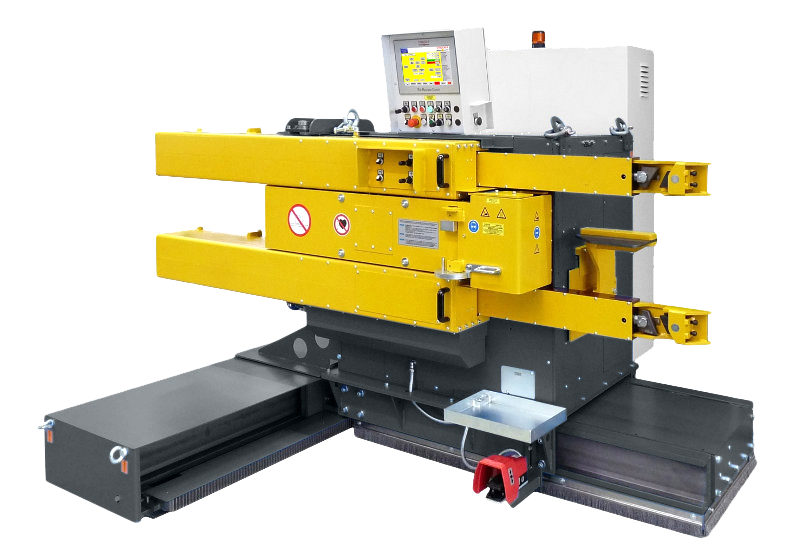

Butt welding of hanging wire coils in the coil radius – STRECKER responded with a machine utilizing a vertical design which allows the welding head very close access to the wire ends needing to be joined, which makes the entire work process much easier.

The machine is designed in such a way that the wires are hydraulically clamped in the coil radius in the clamping fixtures, which eliminates the need for prior straightening. This electric double butt welding machine with automatic deburring, the "SS" in the vertical version, offers many advantages:

Innovation from Strecker

Strecker Type SS120-FPC Vertical

The result

The use of the welding machine, especially with automatic deburring, has brought great improvements, especially in work safety during operations. Accidents during manual deburring in which employees had to be treated with foreign objects in their eyes, for example, have been reduced to nearly zero since these systems have been in operation.

Operators also appreciate the reduced effort required at the welding machine – the work is easier to handle and the entire workflow is simplified.

The welding process employs two upset actions which press the heat-affected material into the weld burr and thus out of the weld joint and ensure very high quality in the weld – which has also reduced the incidence of weld fractures.