Strecker Success Story Reliably weld large cross-sections

The challenge

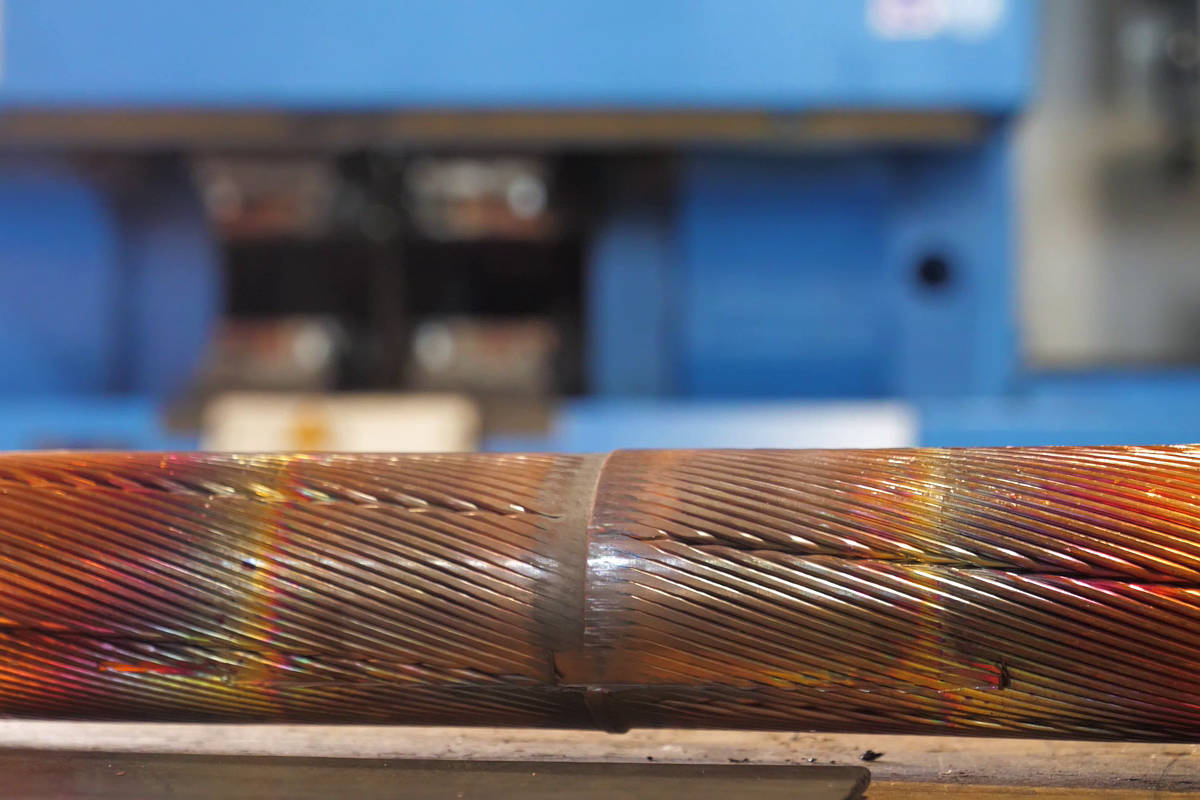

The intention when joining large stranded conductor cross-sections was to avoid unwinding the outer layers to obtain a smaller outer conductor diameter for easier welding. Crimping or using connectors was also to be avoided. And stopping the extruder was an absolute no go due to the hours of effort required afterwards to clean the worm gears.

What is known as the “chamber welding process” uses ceramic tubes, such as STRECKER type SE300 with a welding range for copper conductors of 95-1200 mm². But this was not the first choice here because a lot can be done wrong when preparing the conductor ends to be welded, selecting the tube and setting the individual parameters. The dependence on the experience and the skill of the individual operator is simply too high in this process.

There was a need for a reliable, accurately repeatable welding method that could be carried out safely and conveniently by semi-skilled personnel.

The solution

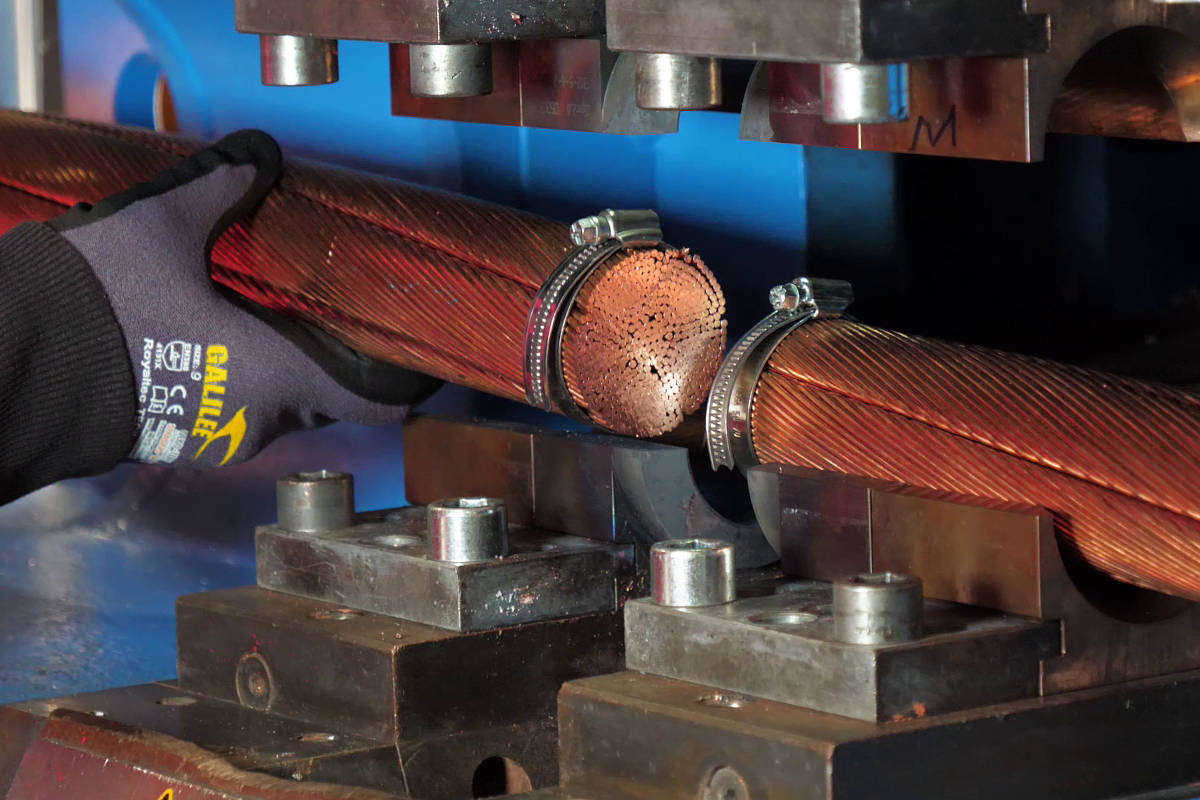

An electrical double-upset butt welding machine with integrated automatic deburring and fully hydraulic motion sequences (clamping, the double upset process and deburring), that can weld completely without tubes so that the operator always has the work sequence in full view.

Here: The STRECKER Type MK1200, welding range for copper stranded conductors, 185-3000 mm².

The result

Using the machine Type MK1200 reduced downtimes and increased productivity.

Operators appreciate the simple handling, especially the integrated recipe management.